Jul 29, 2021 9:30:00 AM

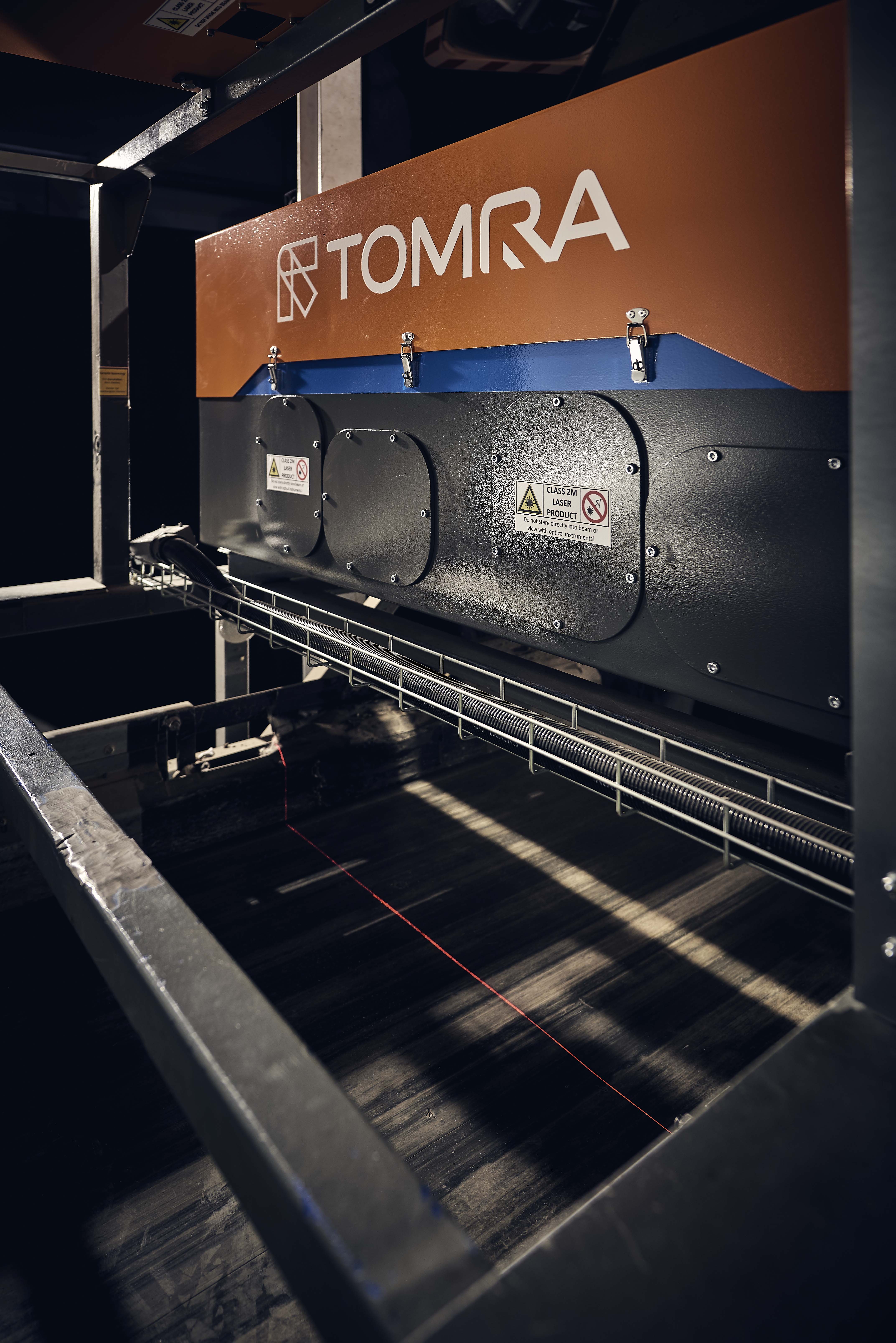

Re-Gen Waste Ltd chooses TOMRA Recycling’s innovative sensor-based technology to transform sorting processes at its industry-leading MRF

TOMRA Recycling’s sensor-based sorting solutions have been chosen to upgrade the processing and quantity of recycled fractions at one of Europe’s most advanced materials recycling facilities (MRFs) in Northern Ireland.